World Class Research and Development

World Class

Research and Development

A well executed design and development cycle for an electronic product requires travel through many stages before arriving at a successful conclusion. Here are the stages that we have determine to create a well designed product.

Concept-

The stage where an idea for a new product, a variation on an existing product, or the identification of a need for an undefined product causes research to be done to define a product, a market, and an approach for manufacturing this product.

Research-

At this stage we utilize the product concept to boost research that includes identifying the technology, methods, and vendors involved in producing the product. This stage results in a detailed design specification that is used to cost the design process that follows as well as the estimated manufactured cost of the product.

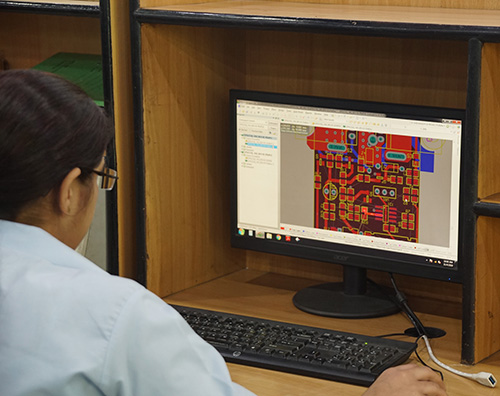

Schematic Designing

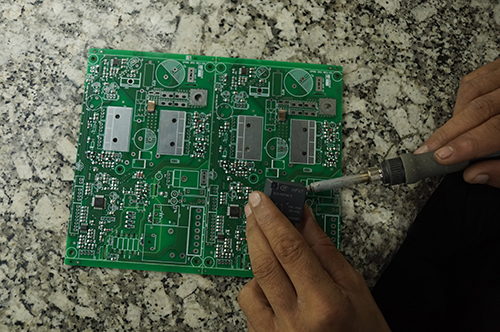

Component Mounting

Hardware & PCB Designing-

Printed circuit boards are typically made with copper. Depending on the requirements, the copper is plated to a substrate and carved away to expose the design of the board. Since there are multiple layers, they must be lined up and bonded together for a secure fit.

The stage of PCB designing involves various process.

- Schematic Designing – Before manufacturing the PCB, we design the board which is done through computer software.Designing a printed circuit board is a detail-oriented process that brings together information from a variety of sources.

- Standard Component Selection – All the required components are selected as per the design and product requirement.

- Printing & Software Designing Of PCB – A special printer is used to print the design of the PCB. It produces a film that shows the details and layers of the board.Copper is pre-bonded to both sides of the layer and then etched away to show the design from the printed films.

- Removing Unwanted Copper – Unwanted copper that remained on the board. A chemical solution, similar to the alkaline solution, eats away at the unwanted copper.

- Inspection – The newly cleaned layers are inspected for alignment.

- Component Mounting – All the components are mounted on PCB as per design.

- Testing & Validation – Before the PCB is considered complete, a technician performs an electrical test on the board. This confirms the PCB functions and follows the original blueprint designs.Changes are done on basis of test results.

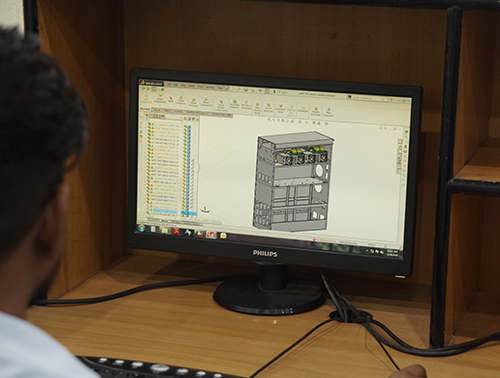

Cabinet Designing

Cabinet Designing (Mechanical Process)-

- Defining the Size – Cabinet size is defined as per the size of all the components using 3-dimensional designing software.

- Prototype – A prototype is developed which undergoes inspection process.

- Assembly – Once the prototype is finalised, assembly of components is done.

Software Programming

Software Programming-

- Selection of controller – Controller selection is done as per the design and requirement of product.

- Flow chart – A detailed flow chart of the software is prepared.

- Software programming – Software for the design is programmed which is simulated and tested.

- Integration – A module is prepared to integrate software with hardware and this is followed by testing process.

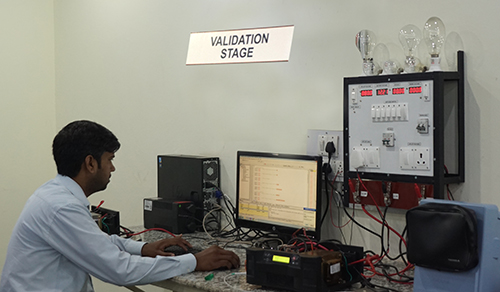

Testing & Validation

Validation-

All the above process is tested and validated and all the trouble shooting process is followed and a final prototype is made and after final testing assembly is done along with drawing finalisation.

It consists of obtaining overall approval for a sequence of activities in order to demonstrate and provide documentary evidence that a specific product can be reliably manufactured via the processes involved.

- Specifications check-As per parameters declared.

- Details of Hardware and Software as per Bill Of Material.

- Charging &Discharging profiles.

- Solar Charging & Functioning.

- Heat & Run Test (20°C-50°C).

- Reliability Test.

Our R&D Pillars

1. Innovation:

In the span of 6 years , R&D team of EAPRO Global Limited initiated and successfully developed many original designed products.

- DSP Sine Wave Inverters.

- RTC(Real Time Clock Technology) with customer friendly saving level options.

- Low cost square wave inverters by RISC technology( Replaced Hardware by Software)

- 6 Channel Interleaved technology MPPT Product range that can utilize up to 99% Solar Power and gives best efficiency out of the Solar Power Generating System.

- Solar PCU up to 100 KW capacity.

- India’s First Remote Controlled AC Stabilizer ( Energy Saving Technology).

- Solar Management Unit – Hybrid SMU.

- Wide range of Battery Equalizer (48V-360V)-Increasing back up.

- Battery Simulator.

- Automatic testing Jig.

- SCA Technology (Sun Clock Approximation).

2. Diversity:

Our R&D keeps on creating ideas for new product development as per market and customer demand.

Our core areas of Diversification are:

- Battery Management System (BMS).

- 3 Phase Grid-Tie Hybrid Inverters.

- Home Automation & Intelligent Surveillance.

3. Sustainability:

A strong sustainability strategy is implemented and followed here.We keep an ambitious approach to renewable energy, delivering sustainable solutions to those in need.

We design our products, validate them and do field testing for providing best in class technology and trusted products with multiple design options.We provide solution for best utilisation of resources with our capability of developing Original Designs.